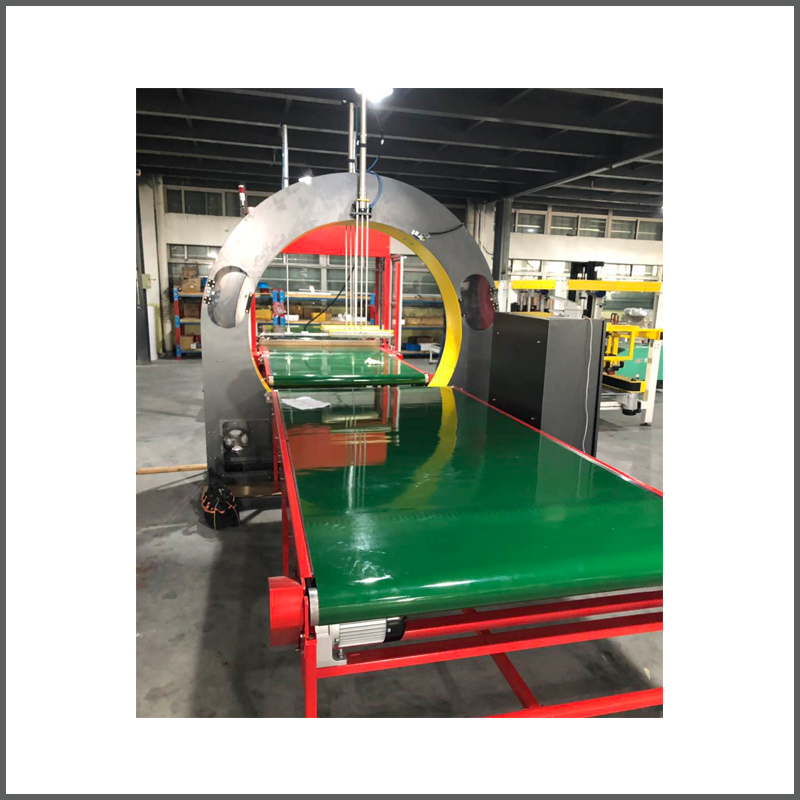

Cupboard cabinet orbital wrapper

* Easy operate screen panel

* Supply with the manual buttons also auto start stop and ring speed control

* Supplied with imported DC motor

* Special design of sealing and cutting machine for bubbles can be customized

DESCRIPTION

Ausim cupboard and cabinet stretch wrapping equipment helps your products to market in pristine condition. Ausim on your specific size/weight/throughput requirements, Dyehome can customize a wrapping system to meet your goals, reduce your packaging costs and assure that your customers receive your products in the same condition you shipped them. Ausim cupboard and cabinet wrap systems can utilize a wide variety of configurations including turntable models, conveyorized models and Orbital (horizontal) models.

Aslo this orbital stretch wrapper used for other products,such as mouldings, profiles, blinds, shelves and kit furniture,furniture, wood panels, cabinets,panels, wooden boards,and bulky products.

Specifications

| Model | SCR-160AC |

| Power | 220V,1P,50/60HZ |

| Air consumption | 0.6-0.8Mpa |

| Film cut/clamp system | By pneumatic |

| Top presser | By pneumatic |

| Inner coil diameter | 1600mm |

| Packing dimension | √W2+H2<1600mm |

| Packing length | Umlimited |

| Conveying method | Belt/roller |

Competitive Advantage

The friction wheel mechanism is adopted to ensure safe, stable and strong operation.

Automatically track the packaging and accurately locate it, which is conducive to operation and ensure safety.

Using a unique tension adjustment mechanism, the tension of the packaging belt is even, and the tension can be increased as needed.

Automatic film clamping, film loading and film breaking operations are safe and efficient.

The guard roller system is encapsulated by polyurethane, which can effectively protect the surface of the product from scratches.

Slow up and slow stop improve the safety of operation.

The independent control cabinet is convenient for operation and maintenance.

The conveying line can be a galvanized drum line, a rubber coated roller line or a belt line, etc.

Two different packaging materials can be wound simultaneously (optional).